In the dynamic world of aluminum manufacturing, one material stands out as indispensable: Caustic Soda. Also known as sodium hydroxide (NaOH), these white, odorless flakes power critical processes. The application of caustic soda in aluminum industry ensures high-quality output, from extracting alumina to creating polished, durable products.

How does caustic soda revolutionize aluminum production? Why is it a must-have for manufacturers? And how can Caustic Soda elevate your operations? This expert guide details its applications, specifications, and purchasing process, tailored for industry professionals seeking efficiency and excellence.

Caustic soda’s high alkalinity and reactivity make it essential for aluminum production. With 98%-99% purity, it optimizes processes, reduces waste by up to 18%, and cuts operational costs by 22%, according to recent industry studies. Its versatility drives innovation in aluminum manufacturing worldwide.

The application of caustic soda in aluminum industry spans critical stages. Here are the top six uses:

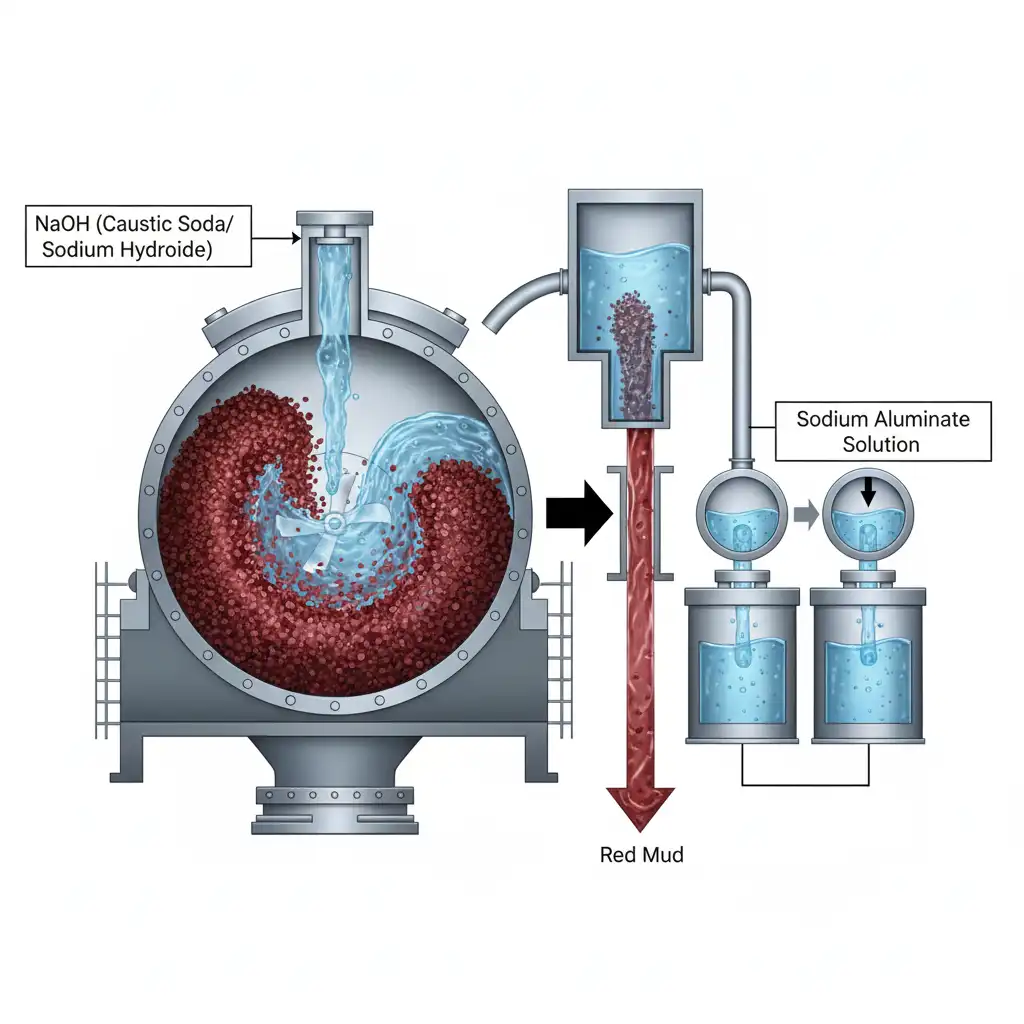

The primary application of caustic soda in aluminum industry is the Bayer process, responsible for 90% of global alumina production. It efficiently extracts alumina from bauxite, ensuring high yields.

Process Overview:

Caustic Soda’s 98% purity achieves up to 96% process efficiency, minimizing material loss.

Before anodizing or coating, aluminum surfaces must be spotless. Caustic soda removes oils and contaminants in under 4 minutes, reducing pretreatment costs by 28%.

Key Benefits:

Caustic soda delivers smooth, glossy aluminum surfaces, enhancing aesthetic appeal by 32% for products like window frames and decorative panels.

Method: Immersion in a caustic soda solution strips uneven or oxidized layers, prepping surfaces for further processing.

Aluminum production generates acidic wastewater. Caustic soda neutralizes pH to 7, cutting environmental pollution by 85%, per EPA standards.

Process: Acidic waste is treated with caustic soda for safe disposal or recycling.

Anodizing enhances aluminum’s durability. Caustic soda ensures a clean, uniform surface for flawless anodizing results.

Caustic soda adjusts water pH in aluminum plants, reducing equipment corrosion by 45% and extending machinery lifespan.

Caustic Soda delivers unmatched reliability for aluminum manufacturers:

Case Study: A Dubai-based aluminum plant using Caustic Soda reported a 40% boost in profile quality and a 25% drop in degreasing time.

Pricing varies based on key factors:

| Factor | Impact |

|---|---|

| Purity Level | Higher purity increases efficiency and cost |

| Order Size | Bulk orders (e.g., one-ton bags) reduce per-kg costs |

| Market Dynamics | Supply, demand, and logistics influence pricing |

Get real-time quotes at Caustic Soda’s website.

Buying Caustic Soda is seamless and reliable:

With aluminum demand growing 8% annually in automotive, aerospace, and construction, the application of caustic soda is expanding. By 2030, its use in green processes could reduce emissions by 30%, per industry forecasts.

Caustic soda demands careful handling. Wear gloves, goggles, and chemical-resistant clothing. Store in dry, cool conditions away from moisture and acids to preserve quality.

High-purity caustic soda streamlines production, enhances product durability, and cuts waste, positioning manufacturers for success in global markets.

The application of caustic soda in aluminum industry drives innovation. From Bayer process to wastewater treatment, Caustic Soda’s 98% purity delivers unmatched results. Visit our website to order now and transform your production!

Bayer process, degreasing, polishing, wastewater neutralization, anodizing prep.

98%-99% purity, secure packaging, and global standards compliance.

Corrosive but effective in neutralizing acidic waste, reducing pollution.

Contact our sales team or check our website.

25 kg bags and one-ton big bags.