When it comes to drilling oil and gas wells, images of massive rigs, hard-hat-wearing engineers, and complex equipment often come to mind. But the truth is, a critical part of this vital process happens at the molecular level, powered by highly effective chemicals like Caustic Soda.

The name might sound familiar, but the application of Caustic Soda in drilling oil and gas wells is a story few know about.

This chemical, scientifically known as sodium hydroxide (NaOH), is not just a powerful industrial cleaner—it plays an indispensable role as a key component in drilling fluids, ensuring the success and safety of drilling operations. Let me make this clear:

Without this substance, drilling operations wouldn’t run as smoothly, and achieving success would be far more challenging. Join us as we dive deep into this topic and uncover the hidden secrets of this versatile material. I’ll show you why Caustic Soda, as a leading producer, can be your trusted partner in this journey.

Before we dive into the details, let’s establish one key point: drilling fluid, or “drilling mud,” is the lifeblood of drilling operations. This fluid serves multiple functions, including cooling the drill bit, transporting drilled cuttings to the surface, and maintaining wellbore stability.

However, drilling fluid alone cannot perform all these tasks effectively. This is where sodium hydroxide, or Caustic Soda, steps in, significantly enhancing its performance.

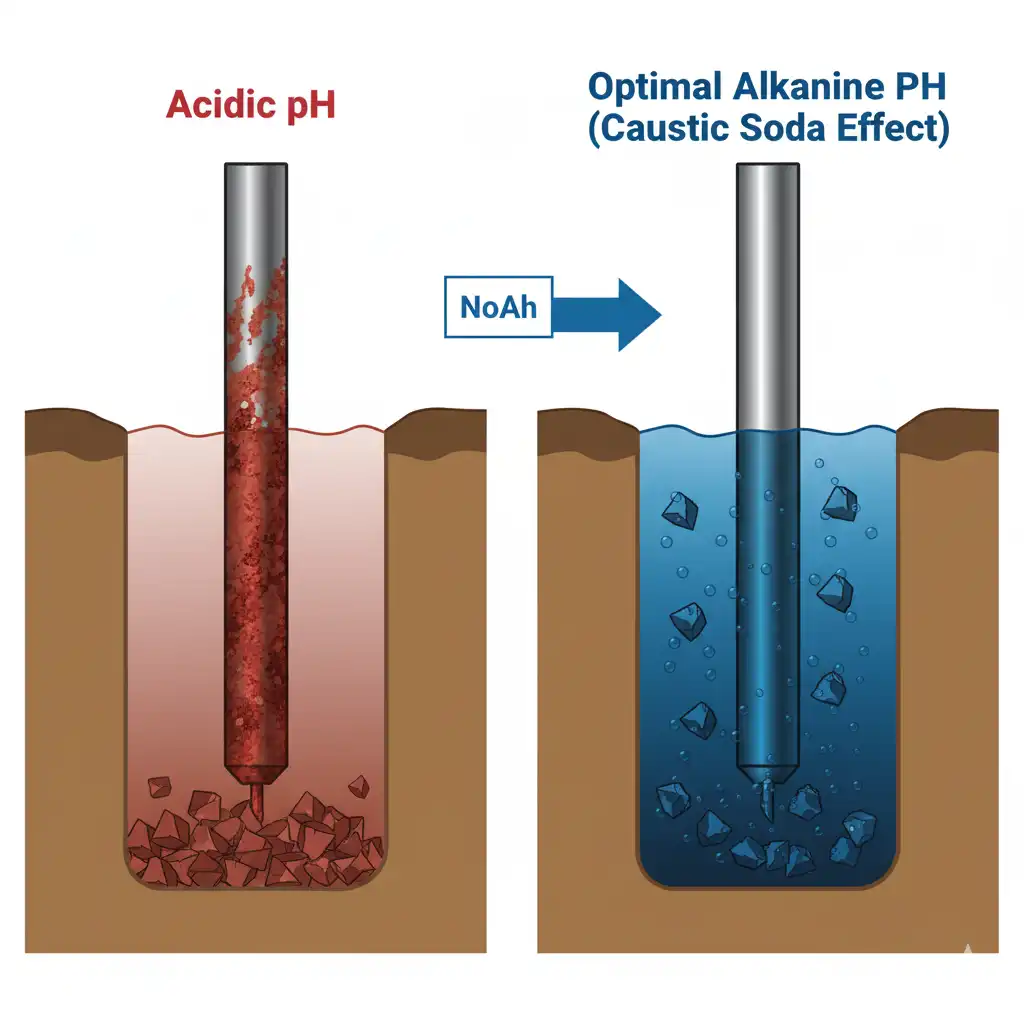

In drilling fluid, Caustic Soda acts as a strong alkaline agent, primarily used for pH control. This pH control is not just a simple adjustment—it’s a complex and critical process that impacts the rheological and chemical properties of the fluid.

A suitable pH level (typically between 9 and 12) prevents several serious issues. If the fluid’s pH shifts toward acidity, disastrous consequences can follow. Let’s take a closer look.

During drilling, acidic gases like hydrogen sulfide (H₂S) or carbon dioxide (CO₂) may be released from subsurface formations. These gases can acidify the drilling fluid, leading to severe corrosion of expensive drilling equipment, such as pipes and bits.

This is where Caustic Soda comes into play, neutralizing these acidic compounds and preventing metal degradation. Simply put: without this process, drilling operations would face significant challenges.

A proper pH level enhances the hydration of polymeric and clay-based materials in the drilling fluid, such as bentonite. When these materials are well-hydrated, the drilling fluid achieves the right viscosity or thickness, which is crucial for transporting cuttings to the surface and preventing their sedimentation.

By increasing the pH, Caustic Soda helps stabilize other additives in the drilling fluid. This prevents thermal degradation of these additives at high well temperatures, maintaining the fluid’s performance at greater depths.

As mentioned, maintaining a pH in the alkaline range allows Caustic Soda to act as a corrosion inhibitor. This significantly extends the lifespan of drilling equipment and reduces maintenance costs.

These are just some of the key applications of this material. In fact, Caustic Soda is one of the most fundamental and widely used components in formulating water-based drilling muds.

| Main Application | Reason for Importance | Impact on Drilling Operations |

|---|---|---|

| pH Adjustment and Control | Maintains fluid in the ideal alkaline range (8.5-10.5) | Prevents corrosion, enhances additive performance |

| Neutralizing Acidic Gases | Counteracts H₂S and CO₂ released from formations | Protects equipment, improves worker safety |

| Viscosity Control | Improves hydration of bentonite and polymers | Efficient transport of cuttings, prevents sedimentation |

| Chemical Stabilization | Prevents thermal degradation of materials at high temperatures | Maintains fluid properties at greater depths |

| Improved Efficiency | Reduces resistance to the drill bit, enhances lubrication | Increases drilling speed, reduces costs |

Knowing this technical information is great, but the real question is: how can you source this vital material with the highest quality? This is where Caustic Soda comes in. At Caustic Soda, we understand that in the oil and gas industry, even the slightest variation in material quality can lead to significant issues and costly setbacks.

That’s why our product is manufactured to the strictest international standards, ensuring that every flake of sodium hydroxide performs its role to perfection.

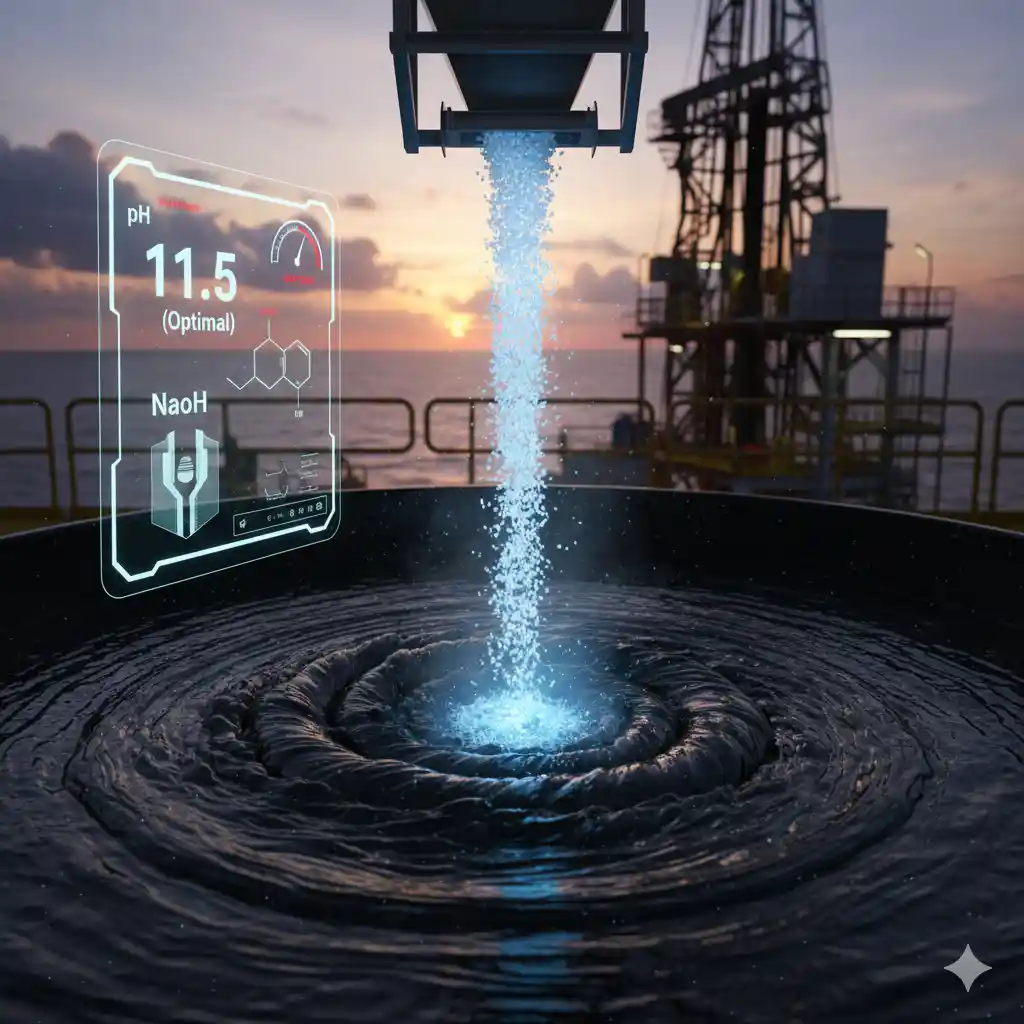

Caustic Soda offers Caustic Soda with a minimum purity of 98% and uniform particle size, making it perfectly suited for sensitive drilling applications. Uniform particle size means our product dissolves easily and quickly in water, preventing the formation of undesirable and hazardous clumps in mixing tanks.

This feature allows operators to control the pH of the drilling fluid with greater precision, reducing operational risks. Trust me, when you’re on the job, the last thing you want to deal with is a chemical that’s difficult to dissolve and increases the risk of burns.

Using a high-quality, standardized product not only simplifies the job but also ensures the safety of your team. This isn’t a small difference—it’s a fundamental one that impacts the entire process.

While Caustic Soda is incredibly useful, it’s also highly corrosive. From years of experience in this industry, I can tell you: never skimp on personal protective equipment (PPE). Use safety goggles, gloves, protective clothing, and a respirator.

Additionally, remember that Caustic Soda releases significant heat when dissolving in water. Always add the flakes slowly to water, not the other way around, to prevent splashing of hot, hazardous solutions. These tips may seem simple, but they can save lives.

When it comes to pricing and purchasing Caustic Soda for industrial applications, you need to act smart. The price of this material depends on several factors, including global raw material prices, currency fluctuations, transportation costs, and, of course, the product’s quality and purity.

However, focusing solely on low prices is a mistake. Low-purity Caustic Soda may contain impurities that disrupt the performance of your drilling fluid or even damage equipment. These hidden costs far outweigh the initial savings of a cheaper product.

At Caustic Soda, we believe in transparent pricing and strive to deliver true value to our customers by offering a high-quality product at competitive prices. For accurate pricing and expert consultation, I recommend contacting our specialists directly. We’re ready to provide the best solutions tailored to your specific needs.

As we’ve seen, Caustic Soda in drilling is more than just a simple chemical. However, some common questions arise that can help you gain a deeper understanding of this material and its applications.

Caustic Soda (NaOH) is a strong base that releases hydroxyl ions (OH⁻) when dissolved in water. Increasing the concentration of these ions raises the pH, making the solution alkaline. This process effectively maintains the drilling fluid’s pH within the desired range.

Yes, sodium hydroxide is available in both flake and liquid forms. However, Caustic Soda flakes are often preferred for drilling due to their solid form and high concentration, making them more suitable for transportation and storage in specific drilling conditions. They’re also easier to dose in some systems.

As mentioned earlier, due to its exothermic and corrosive nature, Caustic Soda must be added carefully and gradually. The best method is to slowly add the flakes to circulating water in the mixing tank to avoid violent reactions and splashing. Using safety equipment during this process is essential.

If you’re looking for a reliable partner to supply your Caustic Soda needs, you’ve come to the right place. At Caustic Soda, with years of experience and technical expertise, we’re ready to meet your needs with a top-quality product at competitive prices. Contact us today for expert consultation and make your drilling operations safer and more efficient.