The oil and petrochemical industries, as the backbone of the modern economy, rely on the precision, safety, and efficiency of chemical processes. In this complex world, every chemical substance plays a distinct role, and the smallest impurity can lead to significant problems.

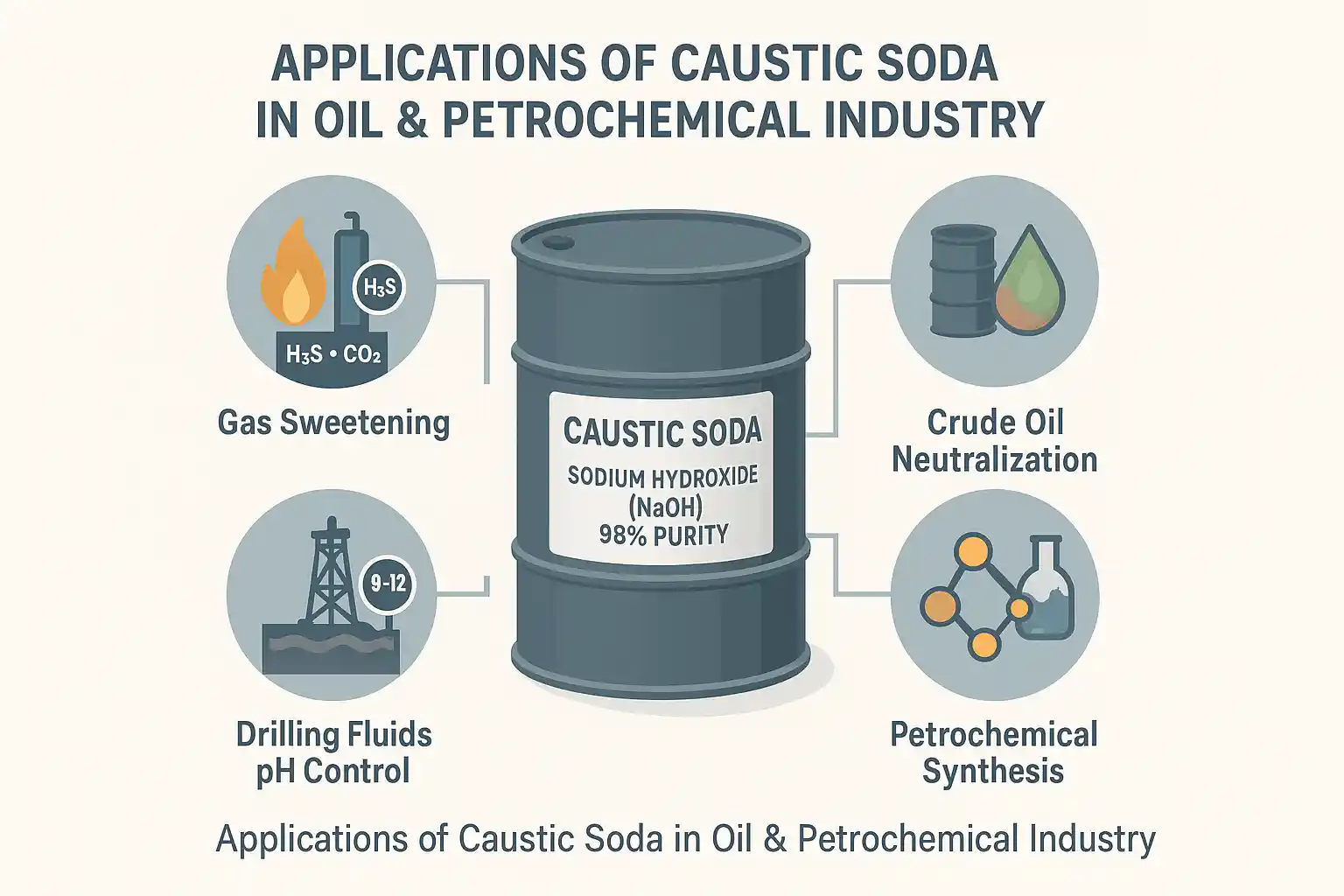

Caustic Soda (Sodium Hydroxide, NaOH), is one of these vital substances, making the application of Caustic Soda in the oil and petrochemical industry a key factor for success. This material plays an irreplaceable role in numerous processes, from refining crude oil to producing petrochemical products.

At Caustic Soda, we understand these complexities. Our product is not just a chemical; it’s a guarantee of quality and safety at every stage of your sensitive processes. This comprehensive guide helps you understand the specialized applications of Caustic Soda in this industry and why choosing a high-quality, standard product from Caustic Soda is a strategic decision.

The role of Caustic Soda in this industry, due to its strong alkaline properties, is extensive. It serves as a neutralizer, catalyst, and cleaning agent in various processes.

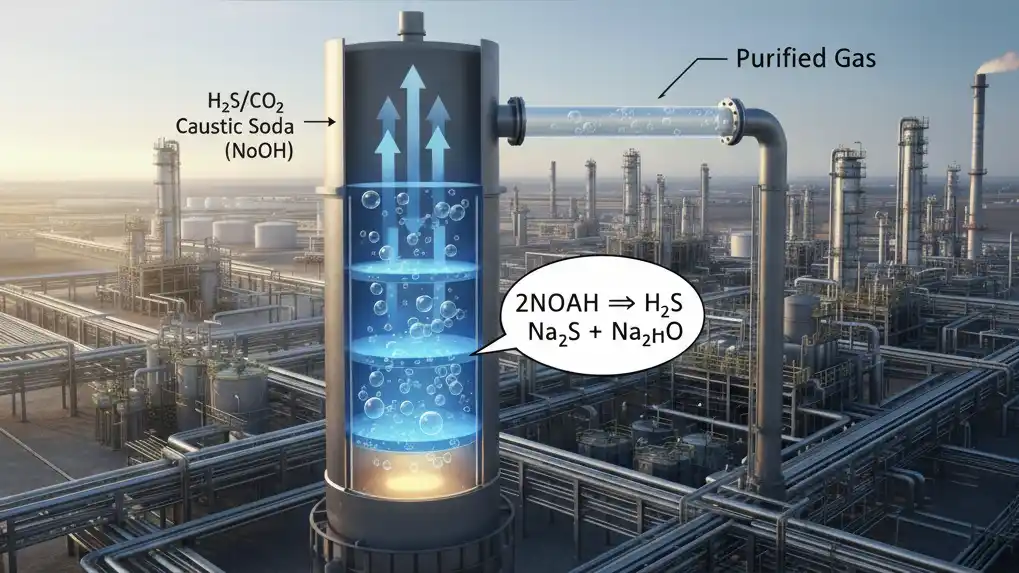

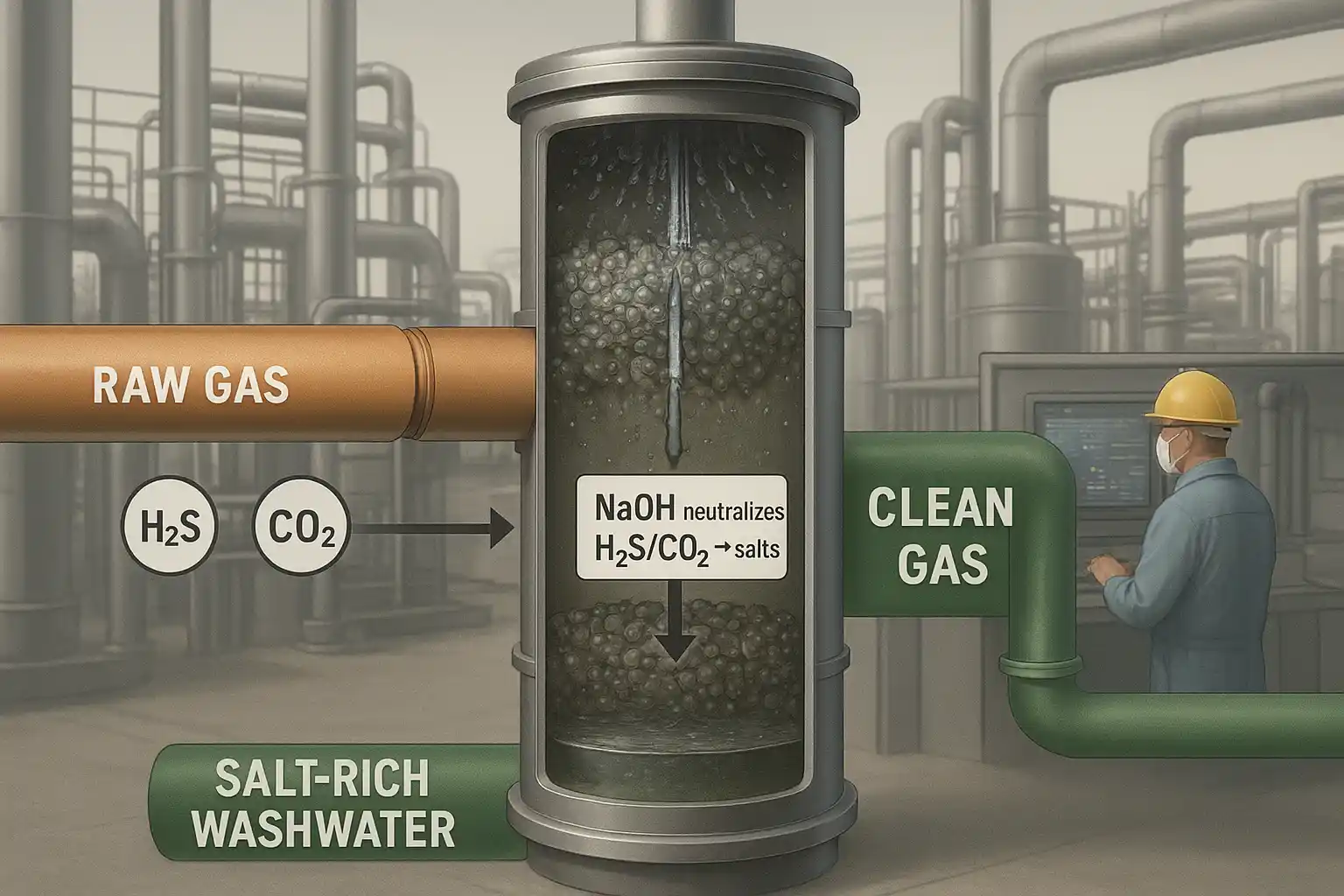

Natural gas extracted from wells often contains unwanted acidic compounds like hydrogen sulfide (H₂S) and carbon dioxide (CO₂). These compounds are not only corrosive to pipelines but also hazardous to the environment and humans.

Crude oil contains various impurities that must be removed before refining into products like gasoline, diesel, or asphalt. One such impurity is naphthenic acids, which can cause severe corrosion in refinery units.

In oil and gas drilling, drilling fluids or “mud” are essential for cooling the drill bit, transporting cuttings to the surface, and stabilizing well walls.

The application of Caustic Soda in the oil and petrochemical industry extends beyond refining. It acts as a raw material or catalyst in producing a wide range of petrochemicals.

| Specialized Process | Main Application of Caustic Soda | Key Benefit |

|---|---|---|

| Natural Gas Purification | Gas sweetening, removing H₂S and CO₂ | Enhanced safety, equipment protection, gas quality |

| Crude Oil Refining | Neutralizing naphthenic acids | Corrosion prevention, improved product quality |

| Oil and Gas Drilling | pH adjustment in drilling fluids | Equipment protection, fluid performance, well stability |

| Petrochemical Production | Catalyst and raw material | Reaction control, key chemical production |

In the oil and petrochemical industry, purity is a necessity, not a choice. Impurities can disrupt processes, poison catalysts, cause unexpected corrosion, and degrade final product quality.

In purchasing industrial chemicals, initial price isn’t the only factor. Low-quality products may seem cheaper but can increase long-term costs through higher consumption, reduced efficiency, and equipment damage.

Caustic Soda helps you make a smart investment with superior quality and competitive pricing. Contact our experts for tailored pricing and consultations.

Caustic Soda with at least 98% purity is recommended to minimize risks in sensitive processes and equipment.

Yes, Sodium Hydroxide is a strong chemical and must be disposed of per environmental regulations, neutralized to a safe pH to avoid ecosystem harm.

Handling requires PPE, including safety goggles, chemical-resistant gloves, and protective clothing. Avoid direct skin or eye contact.

Add Caustic Soda slowly to circulating water using automated dosing systems and alkali-resistant mixing tanks for precise control.

This article explored the application of Caustic Soda in the oil and petrochemical industry. Choosing a high-quality, standard product ensures better results, safety, and process stability.

At Caustic Soda, with years of expertise, we’re ready to meet your needs with top-quality products at competitive prices. Contact us today for expert consultation!