From morning newspapers to packaging and quick notes, paper is everywhere. Ever wondered what transforms rigid wood into smooth, writable sheets? The unsung hero is Caustic Soda (Sodium Hydroxide, NaOH), the backbone of paper manufacturing.

Without Caustic Soda, modern paper production wouldn’t exist. From pulping to recycling, this powerful alkali is critical. This guide explores its role, processes, and why high-purity Caustic Soda is vital.

Caustic Soda, a strong alkaline compound, is a white, odorless solid with high reactivity. In paper manufacturing, it dissolves non-cellulosic components like lignin, enabling high-quality pulp production. With 98%-99% purity, it reduces costs by 20% and waste by 15%.

Centuries ago, wood ash (potassium carbonate) aided fiber breakdown. The industrial revolution demanded stronger alkalis, leading to the Kraft Process in the late 19th century, where Caustic Soda became indispensable for durable paper production.

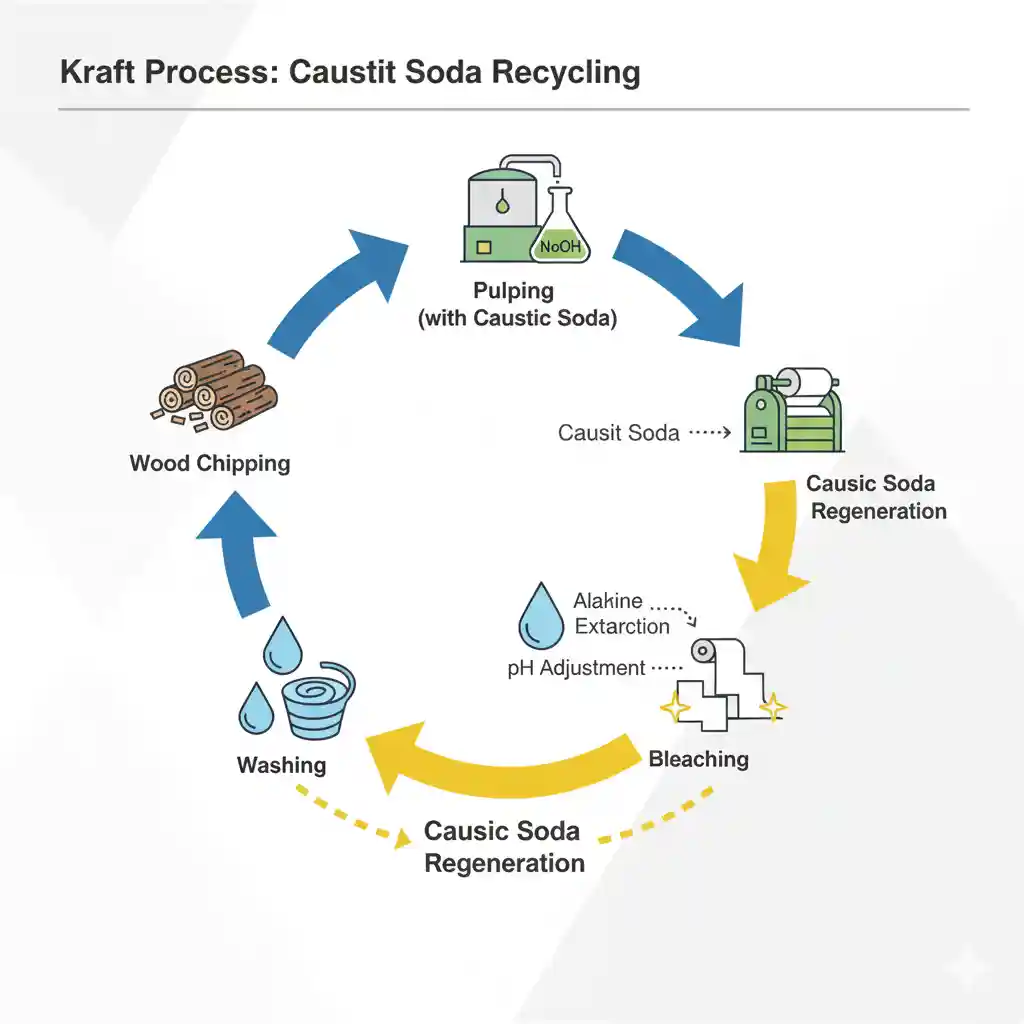

Caustic Soda plays a pivotal role in every stage, from pulping to bleaching.

The primary application of Caustic Soda is in pulping, separating cellulose fibers from lignin.

Wood chips are treated with a solution of Caustic Soda and sodium sulfide (White Liquor) under heat and pressure, dissolving lignin while preserving cellulose. This produces strong pulp for packaging and paperboard.

Though less common, Caustic Soda neutralizes acidic effluents in the sulfite process, balancing pH for environmental compliance.

Brown pulp requires bleaching for white paper. Caustic Soda is key:

It optimizes pH for bleaching agents like chlorine dioxide or hydrogen peroxide, ensuring effective lignin removal.

Post-bleaching, Caustic Soda extracts oxidized lignin, enhancing pulp whiteness and color stability.

In recycling, Caustic Soda detaches ink from fibers via flotation, improving recycled paper quality.

Caustic Soda swells fibers, aiding refining and impurity removal for smoother, high-quality paper.

| Caustic Soda Feature | Impact on Paper Manufacturing |

|---|---|

| High Alkalinity | Efficient lignin removal, bleaching, and deinking. |

| Reactivity | Rapid lignin and impurity separation. |

| Enhanced Product Quality | Whiter, uniform paper with high strength. |

| Recyclability in Kraft | Reduces costs and environmental impact. |

| Cost-Effectiveness | Efficient for large-scale production. |

High-purity Caustic Soda ensures reliable results for seamless operations.

Pricing depends on several factors:

Contact us for quotes tailored to your needs.

Caustic Soda is highly corrosive. Key precautions:

With a 6% annual rise in paper demand, Caustic Soda will drive sustainability, reducing waste by 20% by 2030 through improved recycling and efficient processes.

The application of Caustic Soda in paper manufacturing transforms wood into versatile paper. Order high-quality Caustic Soda from us to ensure superior production!

Pulping, bleaching, deinking, and fiber refining.

98%-99% purity ensures efficiency and quality.

Corrosive but safe with proper precautions.

Contact us or visit our website for quotes.

25 kg bags or one-ton big bags.